News

Aug 12,2024

Damon Empowers Baleno Smart Logistics Center to Open Warehouse Successfully!

Harvest at eighteen, pick fruits in July. On July 18th, 2024, the opening ceremony of Baleno logistics center was successfully held in Dongguan, Guangdong Province, marking that Baleno has made breakthrough in brand operation and logistics efficiency. The intelligent conveying and sorting system composed of i-G5 modular carton conveying line and high-speed loop cross belt sorter, which is the core product of Damon Technology, provides strong support and guarantee for the online operation of Baleno smart logistics center.

Baleno Dongguan smart logistics center project launch ceremony

Baleno Dongguan smart logistics center project launch ceremony

Needs: The business mode has changed greatly, giving birth to smart logistics center construction

Starting from 2023, Baleno launched a new e-commerce channel cooperation and online and offline marketing model, the business transformation has begun to achieve results. Due to the radical innovation of business model, Baleno’s original logistics delivery model faces great challenges, and the new business combination puts forward higher requirements for the processing capacity, timeliness and flexibility of intelligent logistics system. Therefore, Baleno will centralize and integrate small warehouses in Guangdong and Guangxi areas, invest to construct a large automated logistics center, adopt online and offline omni-channel one pallet cargo mode, set goods storage, To B store delivery, To C e-commerce delivery and return processing, goods inventory and other functions in one, only one warehouse can achieve the efficient operation of omni-channel business.

This smart logistics center solution design needs to meet the following omni-channel business needs:

1)To B business: need to support thousands of stores in the region, accumulated daily delivery of 100,000 pieces;

2)To C business: need to support daily tens of thousands of single-stage delivery, and need to support 10 times of daily delivery orders during big promotion period;

3)Return business: To B return business needs to centrally process millions of reverse returns in a quarter during the seasonal change period, To C return often occurs in the instant centralized return after the big promotion period, which poses a certain challenge to daily delivery.

Innovatively designed double-layer steel platform, effectively expand space utilization

Solutions: with small innovation, meet the needs of all-channel one pallet goods

According to the characteristics of Baleno logistics center each business process, Damon has planned an efficient intelligent conveying and sorting system solution, including the core products such as 1+km i-G5 modular intelligent carton conveying line, a high-speed loop cross-belt sorter system, a screw lifter and dynamic weighing equipment.

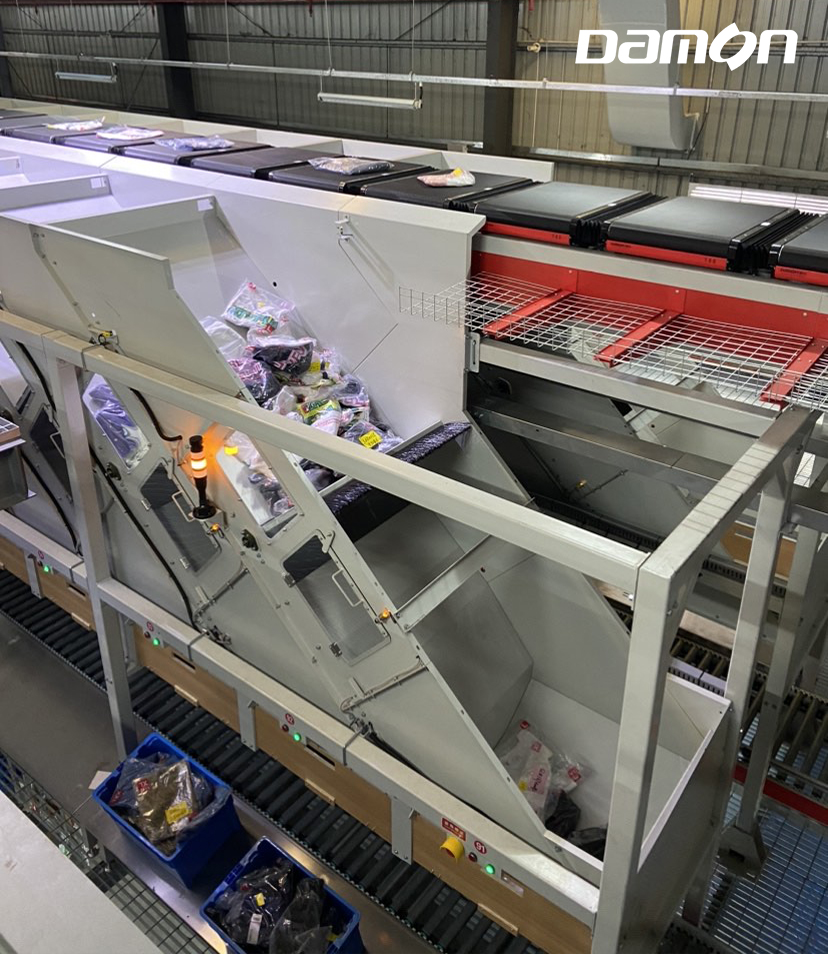

The logistics center has a total land area of about 20,000 square meters and floor height of 10+ meters. Damon has designed a reasonable functional partition for it, which in turn is the whole carton storage area, sorting and packing operation area, zero picking storage area, return inspection and storage area. Among them, the sorting and packing operation area is set up with a total area of 1,800 square meters of high-floor steel platform, which makes logistics center’s over all height fully utilized. The steel platform is set with a cross-belt sorting area, the lower part is divided into receiving and collecting area, To B wave whole carton cache area, To B sorting and collecting area, To C packing area and To C collecting & delivery area, which is mainly docked with the national offline stores and global online e-commerce platform's delivery and return business.

Damon high-speed loop cross-belt sorter system can be effectively compatible with the split case picking operations of multiple orders under the three business scenarios of To B delivery business, To C big promotion delivery business and reverse returns, while simplifying the work process, shorten the time of goods transfer and circulation, and improve the efficiency and accuracy of work. A set of system equipment, supplemented by the off-peak operation plan, can be reused in different time all year round, and equipment utilization rate is significantly improved.

Due to the limited layout space of the high-speed loop sorter system, Damon has innovatively designed the 180 grid ports of sorter for this project, which is the key and difficult point. Unlike the grid ports of standard model, which are inclined outward and extend to the ground, all grid ports are arranged vertically, greatly reduce the overall system footprint and effectively solve the deployment problem of multiple grid ports.

Baleno smart logistic center deploys Damon intelligent conveying sorting system

Value:Project delivery has guarantee, one warehouse delivery high-quality global operations

After the project is officially launched , Baleno logistic center forward and reverse logistics’s timeliness and accuracy have been greatly improved, reduces logistics management difficulty , helps customers easily cope with business fluctuations, guarantee high-quality delivery of "one warehouse delivery globally, goods rotate like wheels".

The system processing capacity reaches tens of thousands of pieces per hour

Average daily receiving tens of thousands of cartons

Daily delivery hundreds of thousands of pieces (To B/C business accumulated, and can effectively cope with flow blowout during the To C big promotion)

Reverse return processing peak value can reach 50,000+ pieces/day

compared to manual picking efficiency increased by 40%-50%

Comparison of scenarios before and after logistics center transformed

Damon Technology always adheres to the exploration and application of intelligent logistics technology, constantly innovates intelligent logistics solutions for the footwear industry, creates more benchmarking projects for footwear logistics automation, helps more head customers achieve omni-channel and high-quality one pallet goods operation, and provides a reference blueprint for the construction and development of intelligent logistics centers in the footwear industry.

Share to: